Overview of Power Generation Gas Turbines

The turbine is the core of any power plant. As the turbine rotates, it drives a generator to produce electricity.

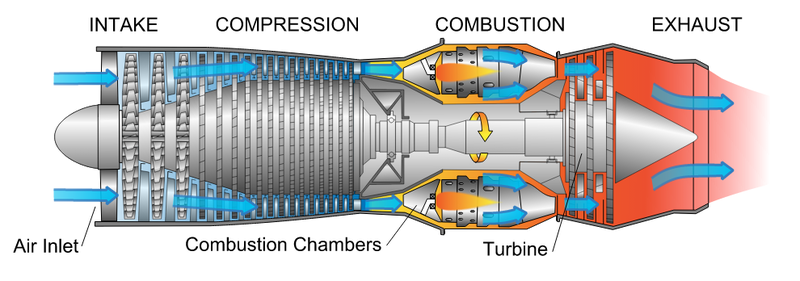

A power generation gas turbine functions by compressing air, mixing it with fuel (typically Natural Gas), combusting the mixture to generate high-temperature, high-pressure gas, and converting this thermal energy into mechanical energy through turbine blades, ultimately producing electricity via a connected generator.

Key technologies for modern gas turbines include:

- Super-alloy materials capable of withstanding temperatures over 1500°C.

- Highly Precision casting for complex high-temperature components.

- Axial compressors with Air compression ratios up to 24:1.

- Low-emission combustor design.

- System integration of compressor, combustor, and turbine components.

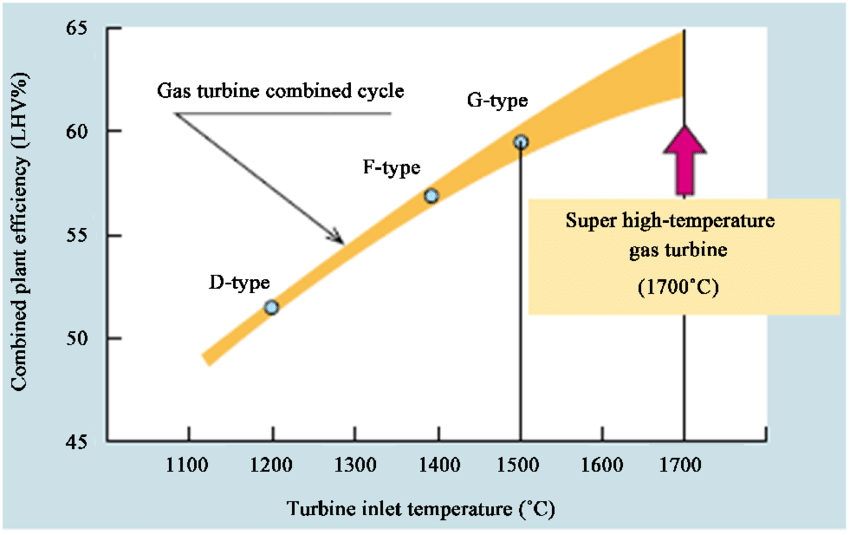

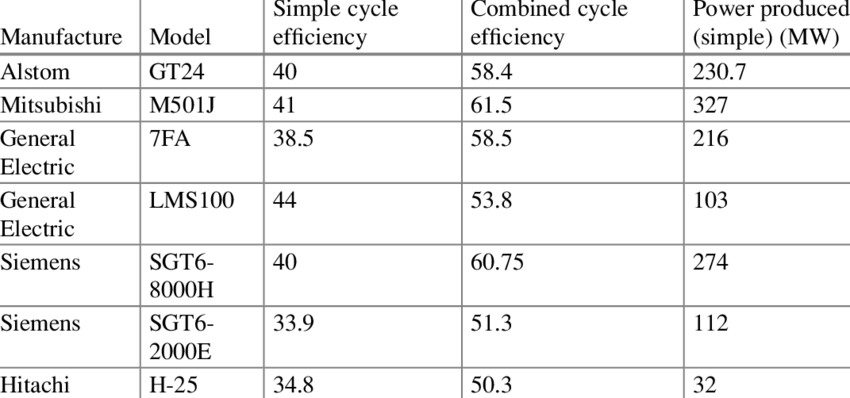

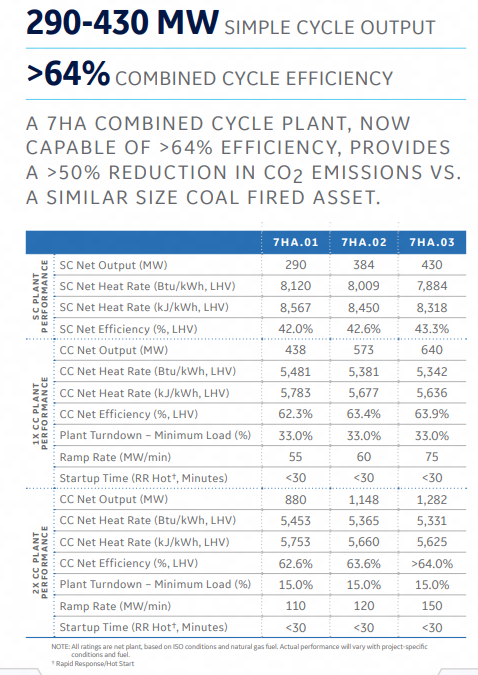

Modern turbines, especially H-Class, reach combined-cycle efficiencies of around 60%.

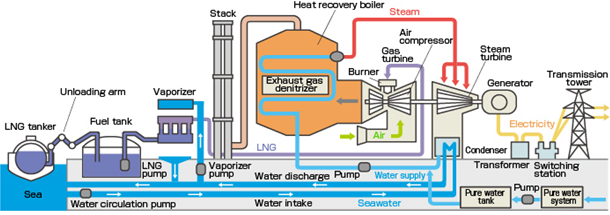

What is Combined Cycle Power?

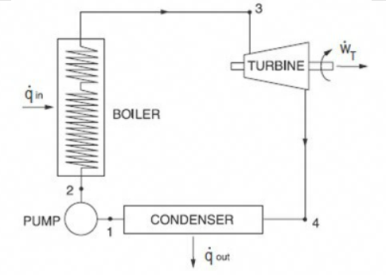

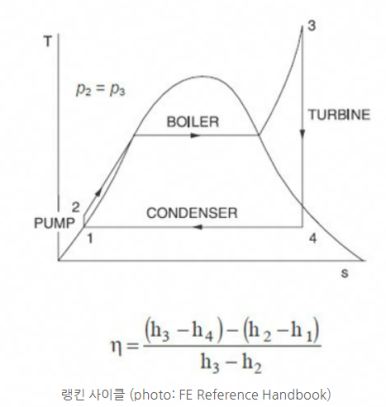

Combined cycle power plants integrate two thermodynamic cycles—Brayton (gas turbine) and Rankine (steam turbine)—to maximize efficiency.

Goals of Combined Cycle:

- Improve thermal efficiency by recovering exhaust heat.

- Example: G/T 35% + S/T 19% = ~54%

- Manage peak loads and provide district heating.

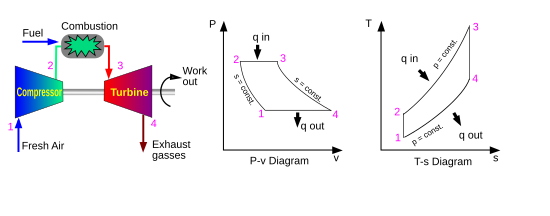

Thermodynamic Principles

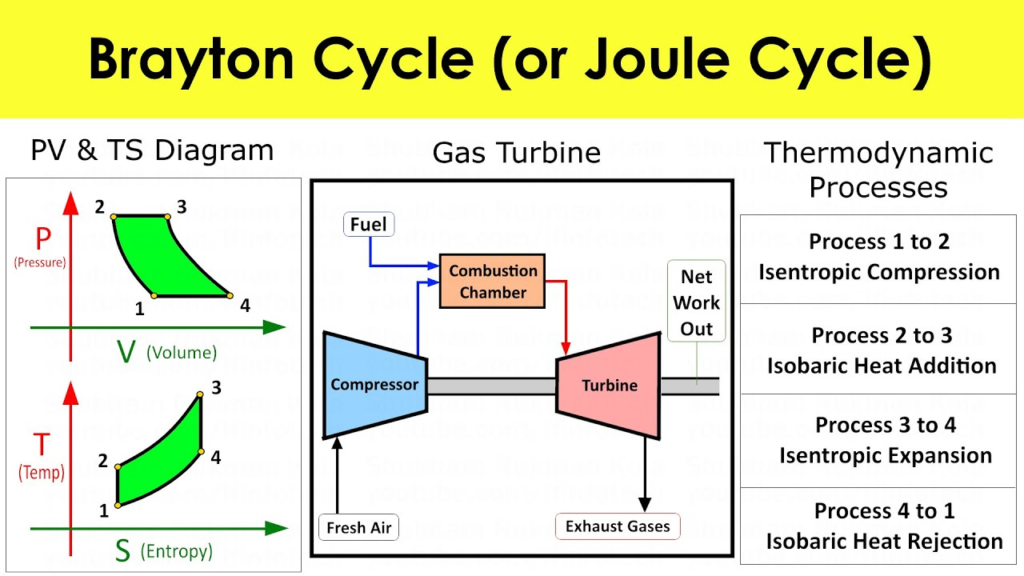

- Brayton Cycle (Gas Turbine – G/T): Compression → Combustion → Expansion → Exhaust

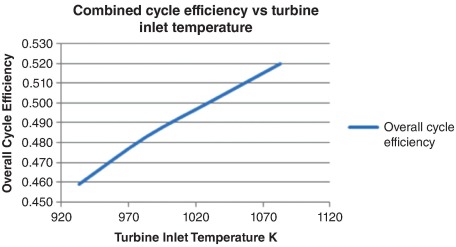

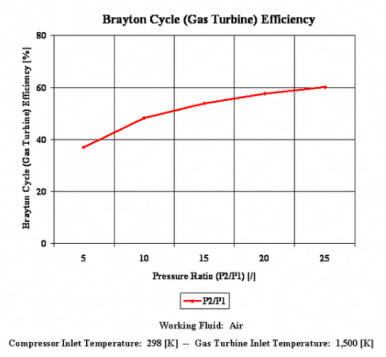

- Efficiency improves with higher pressure ratio and turbine inlet temperature.

- Rankine Cycle (Steam Turbine – S/T): Converts turbine exhaust heat into additional power.

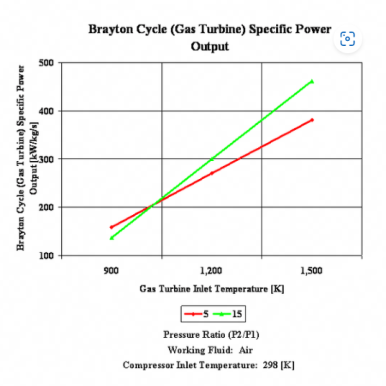

The efficiency of the Brayton Cycle improves as the pressure ratio (Pr) increases and is theoretically independent of the turbine inlet temperature. However, in practice, the actual efficiency is significantly influenced by the temperature of the combustion gas at the turbine inlet — the higher the temperature, the greater the efficiency. Ultimately, the performance of a gas turbine is primarily determined by the airflow rate, pressure ratio, and the temperature of the gas at the turbine inlet.

To improve overall thermal efficiency, maximize the enthalpy difference between turbine inlet (H3) and condenser inlet (H4).

Advantages of Combined Cycle Power

- High thermal efficiency for Combined Cycle Power (up to 50 to 60%)

- Stable efficiency under partial load Operation :

- When output is reduced, individual gas turbines (G/Ts) are sequentially shut down, while the remaining ones operate at full load to maintain high efficiency.

- Short Startup and Shutdown Times

- Gas turbines (G/Ts) can start quickly. Steam turbines (S/Ts) can reach full load within one hour, while conventional boilers (thermal power) require 3 to 20 hours.

- Lower Pollution Emissions (Relatively)

- Emissions from gas turbines using LNG are lower compared to traditional fossil fuels, especially in terms of NOx and SOx.

- Performance Varies Greatly by Fuel Type

- Primary fuel: LNG

- Emergency fuel: Diesel oil (light oil)

Key issues:- Corrosion of turbine blades

- Unburned fuel deposits reducing thermal efficiency

- Efficiency losses due to countermeasures for preventing low-temperature corrosion

- Environmental regulatory compliance

- Shorter Construction Time and Lower Costs (Relatively)

- Gas turbine combined cycle (GTCC) plants can be built faster and more cost-effectively compared to conventional coal-fired or nuclear plants.

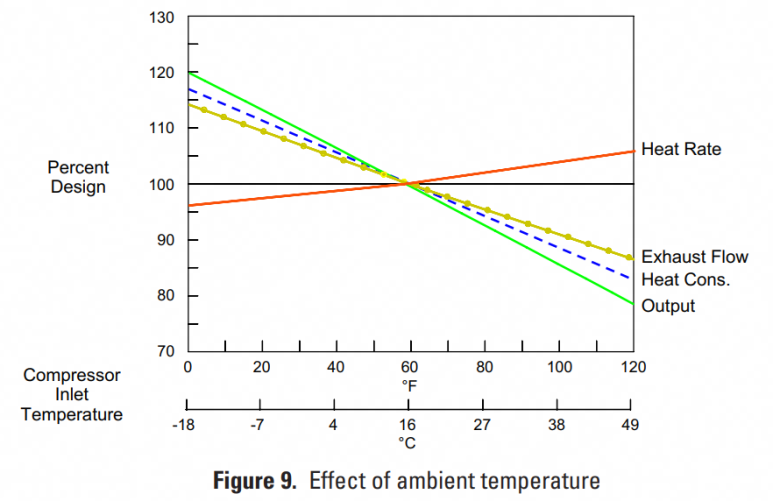

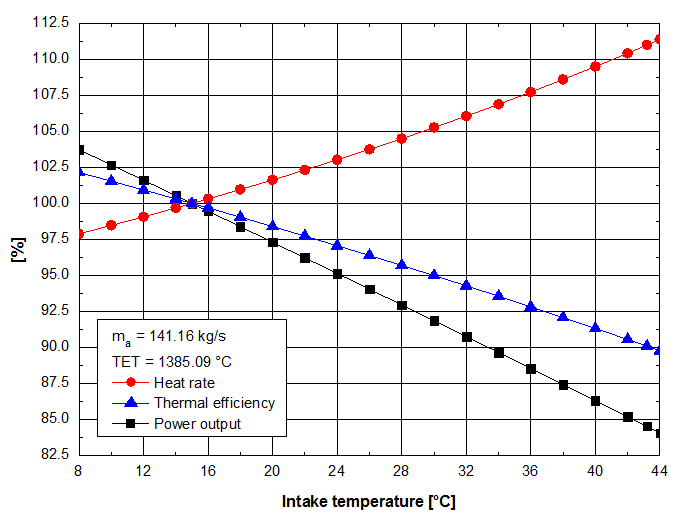

- Maximum Output Varies with Ambient Air Temperature

- Gas turbine performance is directly affected by intake air temperature—higher temperatures reduce output due to decreased air density.

Temperature Effects on Efficiency

Lower ambient temperatures increase air density and mass flow, resulting in:

- Decrease in ambient temperature → 2. Increase in air density (higher specific weight) → 3. Increase in intake air volume + Lower temperature of compressed air → 4. Increase in fuel supply → 5. Increase in Gas Turbine (G/T) output → 6. Increase in G/T efficiency (decrease in Heat Rate, HR) → 7. Increase in exhaust gas volume + Decrease in exhaust gas temperature → 8. Increase in Steam Turbine (S/T) output + Decrease in S/T efficiency → 9. Increase in combined cycle output + Decrease in combined cycle efficiency.

- Higher G/T output

- Lower heat rate (HR)

- Increased exhaust for S/T, raising output but lowering S/T efficiency

- Net combined output increases, but combined efficiency may drop

G/T Performance Factors

- Atmosphere Temperature: When operating at rated load, a gas turbine draws a constant volumetric flow of air across all ambient temperature ranges. As ambient temperature decreases, air density increases, leading to a higher mass flow rate. Additionally, the temperature of the compressed air becomes lower. This cooler compressed air must be heated to the fixed turbine inlet gas temperature, which results in increased fuel consumption. Consequently, the gas turbine output increases as ambient temperature drops. However, since the rate of increase in output exceeds the rate of increase in fuel consumption, the gas turbine’s heat rate decreases.

- G/T: As ambient temperature decreases, efficiency increases (heat rate decreases).

- S/T: As ambient temperature decreases, efficiency decreases (but output increases).

- Combined Cycle: As ambient temperature decreases, overall efficiency decreases.

- Gas Turbine Inlet and Exhaust Gas Temperatures : (1) (G/T) Higher inlet temperature and lower exhaust temperature lead to increased efficiency (2) (S/T) Higher exhaust temperature results in increased efficiency (3) Combined Cycle: Higher inlet and exhaust temperatures both contribute to improved efficiency.

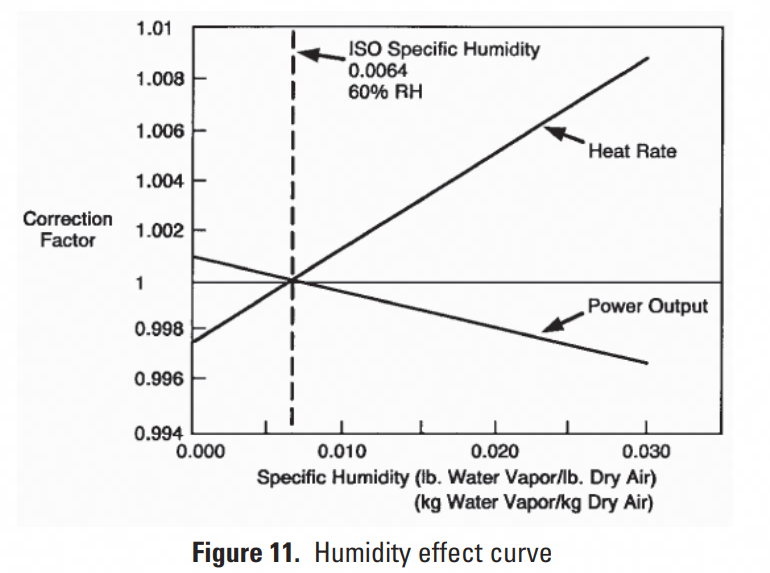

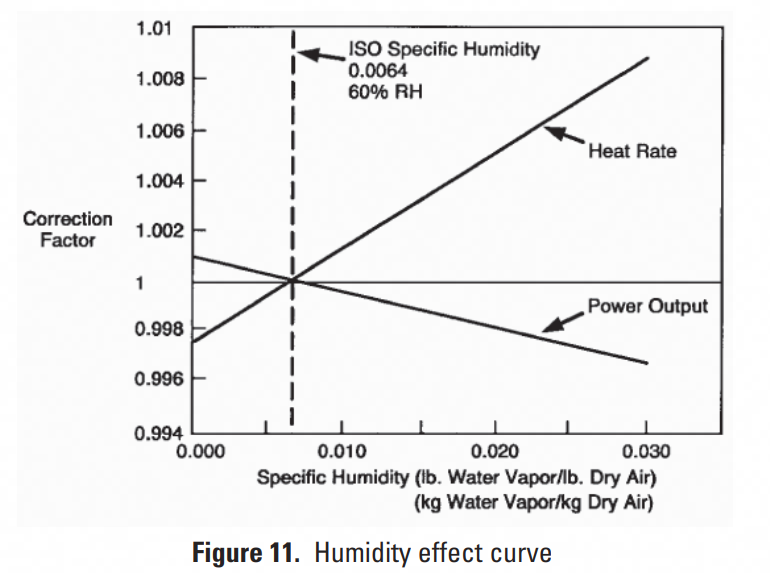

- Humidity:Ambient humidity affects not only the air mass but also the enthalpy of the intake air. Although the impact of humidity is relatively minor, it has a negative effect on turbine efficiency. Additionally, humidity influences the amount of steam or water injection required for NOx suppression.

- Atmospheric Pressure:

- Atmospheric pressure affects gas turbine performance in a similar way to ambient temperature. As pressure increases, air density rises, leading to a higher mass flow rate through the turbine. However, unlike temperature, the increase in fuel consumption matches the increase in output, so the gas turbine’s heat rate remains unchanged.

- G/T: Higher atmospheric pressure increases air mass flow, boosting output. Efficiency remains unchanged (fuel consumption rises proportionally with output).

- S/T: Higher atmospheric pressure leads to greater G/T exhaust flow, increasing steam turbine output.

- Combined Cycle: Since both heat supply and air mass flow rise proportionally with pressure, overall efficiency remains constant.

- Atmospheric pressure affects gas turbine performance in a similar way to ambient temperature. As pressure increases, air density rises, leading to a higher mass flow rate through the turbine. However, unlike temperature, the increase in fuel consumption matches the increase in output, so the gas turbine’s heat rate remains unchanged.

- Compressor Pressure Ratio:

- Higher pressure ratio = better G/T efficiency

- S/T efficiency may decline

- Combined cycle needs balanced pressure ratio for increasing efficiency

- Operating Hours:

- Long-term operation can cause corrosion, erosion, and fouling—requiring regular inspection and maintenance.

Understanding Heat Rate (HR)

The heat rate is a common term used in power plants to indicate the efficiency of electricity generation. It is the inverse of efficiency—meaning a lower heat rate indicates better performance.

- Heat Rate = Energy input / Electricity output

- Unit: kcal/kWh, MJ/kWh, or Btu/kWh

- Lower HR = higher efficiency

- At 100% efficiency: HR = 860 kcal/kWh = 3,412 Btu/kWh = 3.6 MJ/kWh

Relationship:

- HR = 860 / Efficiency(%)

Calorific Value (Heating Value)

- LHV (Low Heating Value / NCV): Excludes latent heat from steam condensation

- HHV (High Heating Value / GCV): Includes latent heat

The difference between HHV and LHV can be ~10%.

Formula:

- LHV ≈ 0.933 * HHV – 313.3 kcal/Nm³

- If HHV = 10,400 kcal/Nm³ → LHV ≈ 9,393 kcal/Nm³

Why Calorific Value Matters

Fuel procurement teams must consider not only heat rate and plant efficiency but also the heating value of LNG. For instance:

- A 10% difference in calorific value alters required fuel volume.

- It impacts LNG terminal rental capacity and import strategy.

Example: GE’s 7HA turbine performance specs state output, HR, and efficiency—all based on LHV.

Conclusion

The fuel consumption of a gas-fired power plant is influenced by:

- Heat rate

- Thermal efficiency

- Fuel calorific value

Even when the HR and capacity are fixed by EPC/design teams, LNG procurement teams must focus on calorific value to assess import volume and regasification terminal capacity requirements effectively.

End.