Overview of Combined Cycle Power Generation (CCPP)

Definition:

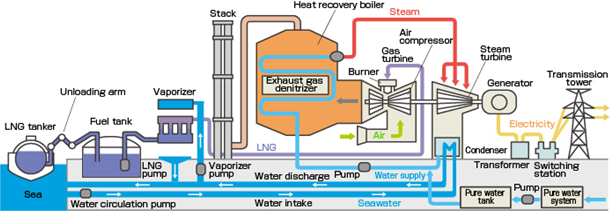

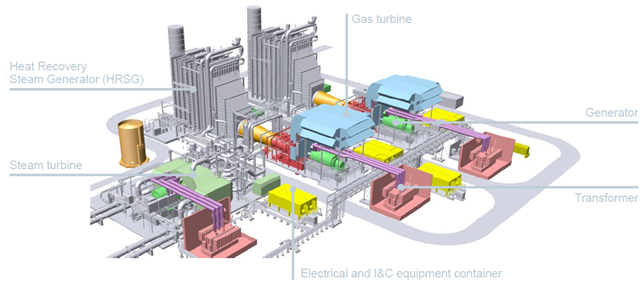

Combined Cycle Power Generation (CCPP) is a highly efficient electricity generation method that utilizes both gas and steam turbines in a single cycle. It combines two thermodynamic cycles — the Brayton cycle (gas turbine) and the Rankine cycle (steam turbine) — to maximize the energy extracted from fuel.

Principle of Combined Cycle Power Generation

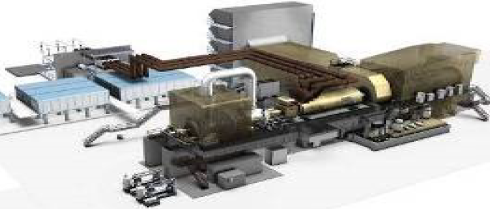

A combined cycle power plant integrates two types of power generation cycles into a single system(Gas Turbine + HRSG + Steam turbine) to enhance thermal efficiency. Hot exhaust gases from the gas turbine (above 500°C) are fed into a Heat Recovery Steam Generator (HRSG), which produces steam to drive a steam turbine.

Advantages Over Other Generation Sources:

- High Thermal Efficiency: While simple(single) gas turbines offer ~40% efficiency and coal-fired plants ~45% vs. combined cycle systems can reach ~60%.

- Cost-Effective Investment: Lower capital costs, construction time, and land requirements than coal and nuclear plants.

- Capex: Combined cycle $800–900/kW; Coal $2,400/kW; Nuclear $4,500/kW

- Construction Time: Combined cycle 3 years; Coal 5 years; Nuclear 7 years

- Fuel Flexibility: Modern gas turbines can run on natural gas and diesel. With appropriate combustor specs, hydrogen-natural gas co-firing is also possible.

- Operational Flexibility: Gas turbines ramp up to peak load in about 1/4 the time of coal plants.

- Other Benefits: High reliability, low maintenance costs, and environmental friendliness.

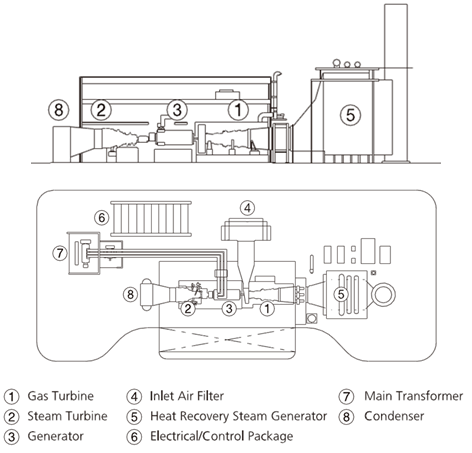

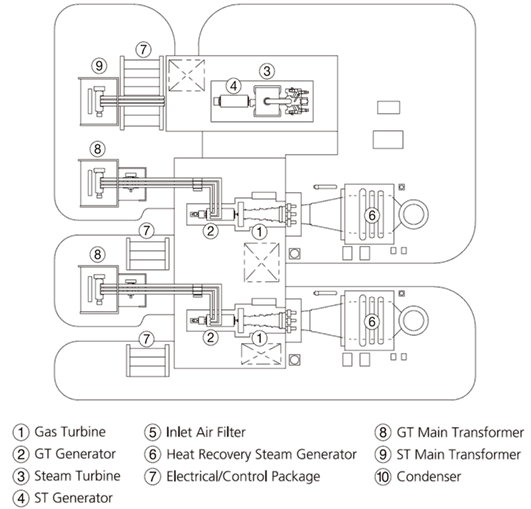

Plant Configuration Types:

| Classification | Single Shaft (Case : MHPS Company) | Multi Shaft (Case : MHPS Company) |

Layout |  (8) Condenser – (2) ST – (3) Generator – (1) GT – (5) HRSG |   (ST Generator) – (ST) – (Condenser) (GT Generator) – (GT) – (HRSG) (GT Generator) – (GT) – (HRSG) |

| Required space | MHPS M501J Model : 160m × 80m (Power Block) | MHPS社 M501J Model : 140m × 140m (Power Block) |

| Control System | Individual control systems for GT, HRSG, and ST | Individual control systems for GT, HRSG, and ST & Central control system |

| Note | Relatively easy to operate in terms of output adjustment for start-stop and load variation | In the case of a 2-2-1 configuration, larger-capacity steam turbines can be used compared to a single-shaft 1-1-1 configuration |

Power generation efficiency and output:

- The pressure ratio of the air compressor and the Turbine Inlet Temperature (TIT) are key factors in gas turbine efficiency.

- As TIT and pressure ratio increase, thermal efficiency also improves.

- TIT used to be around 1,000°C in the past, but it has now been developed to approximately 1,600°C.

- As TIT and pressure ratio increase, thermal efficiency also improves.

- Lower ambient temperature and higher pressure improve GT output.

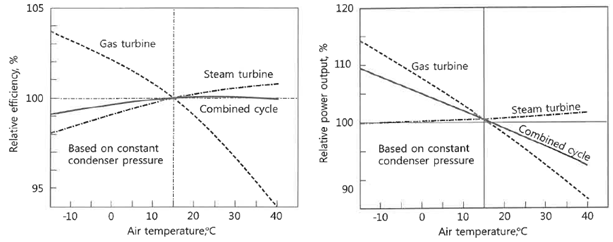

- (Below Graph : Changes in Combined Cycle Thermal Efficiency (Left) and Power Output (Right) According to Ambient Temperature Variations)

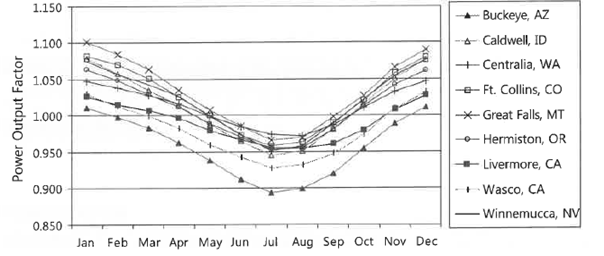

- (Below Graph : Monthly Comparison of Combined Cycle Power Output (Higher Output in Winter Season)

Heat Performance Comparison

The efficiency of combined cycle power generation can vary depending on the configuration of major equipment, load conditions, LNG composition, and cooling water or ambient temperature.

Therefore, a review of various combinations of these conditions is necessary to optimize performance.

Accordingly, the plant should be designed to achieve optimal output and efficiency from an economic perspective, taking into account different power generation scenarios.

An example calculation using GT Pro (thermal performance software) under 100% load and 15°C ambient conditions shows the following efficiency ranking:

7HA.02 (GE) > M501J (MHPS) > SGT6-8000H (Siemens)

While differences exist by model, efficiency tends to decrease by approximately 1.5 percentage points compared to standard conditions due to ambient temperature rise,

and by about 5 percentage points under 50% load conditions.

(Case Selection : Project owner has recently selected GE as the major equipment supplier.)Efficiency is influenced by configuration, load, LNG composition, and cooling methods. Design optimization should consider various combinations.

Example (100% Load @ 15°C, GT Pro software):

| GT Model (By Manufacture) | M501J (MHPS) | SGT6-8000H (Siemens) | 7HA.02 (GE) | |||

| Conditions | Output(kW) | GT (Gross) | 323,728 × 2 | 284,865 × 2 | 331,028 × 2 | |

| ST (Gross) | 329,259 × 1 | 304,457 × 1 | 397,220 × 1 | |||

| Plant (Gross) | 976,715 | 874,188 | 1,059,276 | |||

| Power Consumption | 17,703(1.813%) | 16,280(1.862%) | 20,089(1.897%) | |||

| Plant (Net) | 959,012 | 857,907 | 1,039,254 | |||

| Heat Rate(kcal/kWh) | Plant (Gross) | 1,368.1 | 1,412.5 | 1,297.9 | ||

| Plant (Net) | 1,393.4 | 1,439.3 | 1,322.9 | |||

| Efficiency (%) | Plant (Gross) | 62.85 | 60.87 | 66.25 | ||

| Plant (Net) | 61.71 | 59.74 | 64.99 | |||

| Ambient Temp. & Efficiency(%) according to Loading | Ambient Temp. | -12℃ | 60.90 | 58.79 | 63.54 | |

| 15℃ (High Efficiency) | 61.71 | 59.74 | 64.99 | |||

| 32℃ | 60.39 | 58.51 | 63.42 | |||

| Loading | 100% | 61.71 | 59.74 | 64.99 | ||

| 90% | 60.87 | 59.23 | 64.69 | |||

| 80% | 60.35 | 58.46 | 64.14 | |||

| 75% | 59.92 | 57.98 | 63.8 | |||

| 60% | 58.26 | 56.11 | 62.23 | |||

| 50% | 56.76 | 54.42 | 60.71 | |||

| 40% | 54.74 | 52.06 | 58.82 | |||

| 35% | 53.17 | 50.55 | 57.51 | |||

| 20% | 45.12 | 43.11 | 52.36 | |||

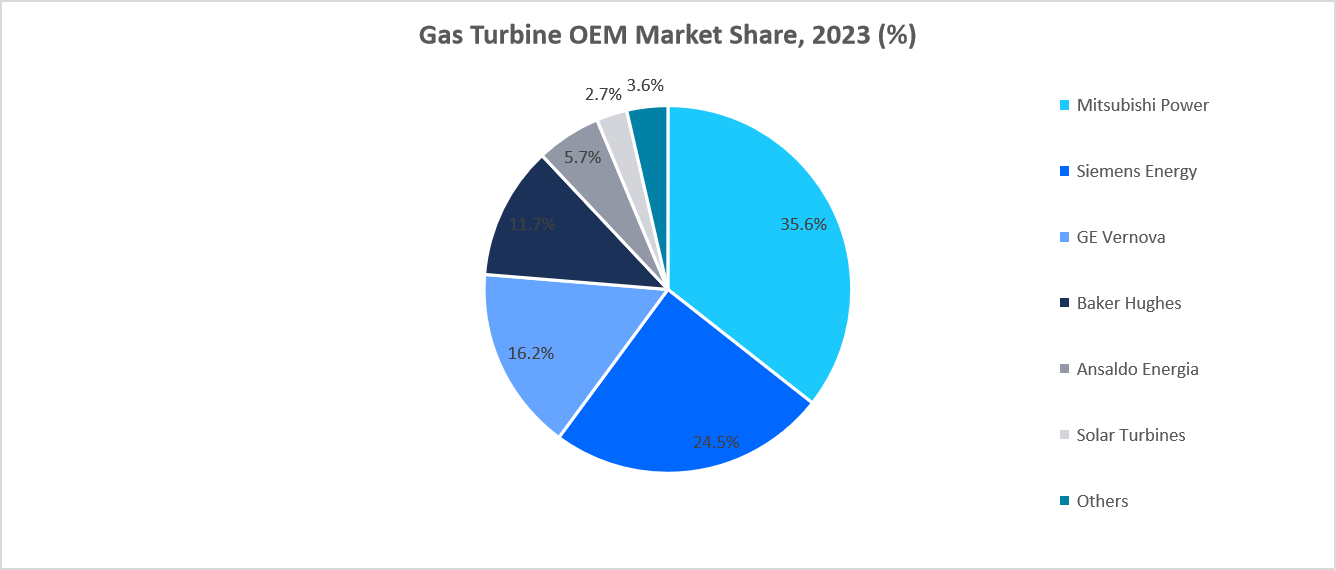

Global Gas Turbine Market:

- In 2023, Dominated by MHPS (35%), Siemens (24%) and GE (16%).

Key Manufacturers:

| MHPS (Mitsubishi Hitachi Power Systems) | Siemens | GE (General Electric) | |

| Company History | In 1965, MHI (Mitsubishi Heavy Industries) began manufacturing gas turbines as a latecomer through a technical partnership with U.S.-based Westinghouse. In the 1990s, the Japanese government supported the development of advanced gas turbines. In 2014, MHI and Hitachi integrated their power generation divisions to establish MHPS (Mitsubishi Hitachi Power Systems), with MHI holding 65% and Hitachi 35%. In 2020, MHI acquired 100% of the shares and announced a name change to “Mitsubishi Power.” In Q1 2020, MHPS received orders totaling 2,638 MW, ranking #1 globally with a 28.1% market share. This includes a recent order for two M501JAC models for hydrogen co-firing by the Intermountain Power Agency in Utah, USA. | Started as a German telegraph company in 1850, and installed its first industrial gas turbine in 1956 Acquired UK-based C.A. Parsons in 1997 (Parsons: inventor of the steam turbine) Acquired the power generation division of U.S.-based Westinghouse in 1998, gaining large gas turbine manufacturing technology and entering the U.S. market Acquired UK-based Ruston Hornsby in 2003 Acquired the energy division of Rolls-Royce in 2014 | Founded by Edison in 1878 Started the gas turbine business in 1918 Acquired gas turbine manufacturer JBE in 1999 (JBE founded in 1948, Scotland) Acquired Alstom’s power business in 2015 Secured a total of 1,500 MW capacity, including 500 GW of Alstom’s power generation assets At that time, Alstom held about 25% of the global power generation equipment market Acquired Doosan Engineering & Construction’s Heat Recovery Steam Generator (HRSG) business in 2016 |

| Main Model (@60Hz) | M501J: Developed in 2011 Applied its proprietary turbine blade coating technology, achieving high-temperature combustion (~1,600°C) and high efficiency, with strong performance validated through many installations A drawback is the need to use steam (not air) as the combustor cooling medium, which requires a larger auxiliary boiler M501JAC: Developed in 2015 Uses air-cooled combustor Achieves approximately 64% efficiency | SGT6-8000H: Developed in 2010 A 410 MW single-shaft combined cycle power plant. Since it uses an air cooling system, auxiliary boilers are not required, but due to HRSG design limitations, additional equipment is needed for gas turbine standalone operation ※ A sales strategy is in place to supply the SGT6-8000H gas turbine model as a package with a Long Term Service Agreement (LTSA) SGT6-9000HL: Developed in 2017. As the latest model, a supply contract for GT/ST/HRSG and generator was signed with SK E&C at the end of 2019 for the Yeoju Combined Cycle EPC Turn-key project Achieves combined cycle efficiency of over 63% | 7HA.01: Developed in 2012, supplied to France, Japan, Russia, the U.S., and other countries Set a world record efficiency of 63.08% (60Hz) at Chubu Electric Power’s Nishi-Nagoya plant in Japan 7HA.02: Developed in 2014 Combined cycle efficiency of 63.6% (Net, 2-2-1 configuration) 7HA.03: Developed in 2019 Latest model with largest unit capacity and highest efficiency (Net over 64%) Signed a supply contract with FPL (Florida Power & Light) in October 2019 |

Specific Considerations For Selecting GT:

Gas Supplying Pressure

- If the gas supply pressure does not meet the required pressure for each GT model, a booster (Fuel Gas Compressor) needs to be installed

| Model | M501J | SGT6-8000H | 7HA |

| Fuel Gas Pressure _ required (kg/cm2g) | Approx. 46 | >39 | >36 |

Water Demand

- The intake and discharge method, location, and cooling water requirements must be determined through a recirculation study comparing the investment cost of the intake/discharge facilities with the limit on intake water temperature rise due to thermal discharge (e.g., less than 1°C)

- Required Water Demand (@ 1GW Basis calculated by GT Pro)

| GT Model | Gross Power (KW) | Condenser water demand (Ton/h) | Cooling water demand (Ton/h) | Total Required Water (Ton/h) |

| M501J | 976,714 | 62,100 | 3,600 | 65,700 |

| SGT6-8000H | 874,188 | 60,564 | 3,343 | 63,907 |

| 7HA.02 | 1,059,276 | 79,368 | 3,905 | 83,273 |

Estimated Auxiliary Steam Requirement

- During plant operation, startup, and shutdown, the steam required within the facility is supplied from the auxiliary boiler (during normal operation, steam is supplied from the HRSG).

- Depending on the gas turbine model, the need for an auxiliary boiler and its capacity may vary.

- < Example of Estimated Auxiliary Steam Requirement (1 GW class) >

| Items | M501J | SGT6-8000H | 7HA |

| Steam for gas turbine combustor cooling | 134.3 | – | – |

| Steam for steam turbine sealing | 7.4 | 7.4 | 7.4 |

| Steam for steam turbine sealing | 1.2 | 1.2 | 1.4 |

| Steam for DeNOₓ system | 0.4 | 0.4 | 0.4 |

| Others | 6.2 | 6.2 | 6.2 |

| Total | 149.5 | 15.2 | 15.2 |

※ The M501J model (by MHPS) uses steam cooling, therefore an auxiliary boiler is essential.

Global Application Trends in 2018 – 2019 (referenced by 2020 Gas Turbine World Handbook)

| GT Vendor | MHPS | Siemens | GE | ||

| GT Model | M501JAC | SGT6-9000HL | 7HA.01 | 7HA.02 | 7HA.03 |

| Numbers (Contracted) | 9 | 9 | 2 | 23 | 1 |

| (Contracted #)xMW | 3,800 | 3,648 | 580 | 8,832 | 430 |

| Occupied Rate | 22% | 21% | 3% | 51% | 2% |

| GT Model(Vendor) | Nation | Owner/Project | Unit no. | Unit ISO rating(MW) | Remarks |

| M501JAC(MHPS) | Brazil | Marlim Azul | 1 | 425 | |

| Brazil | Vale Azul II | 1 | 400 | ||

| Canada | Suncor Energy | 2 | 425 | Cogen | |

| U.S | Danskammer Energy | 1 | 425 | ||

| U.S | J-Power USA Development | 2 | 425 | ||

| U.S | NTE Energy | 1 | 425 | Dual Fuel | |

| U.S | PowerSouth | 1 | 425 | ||

| SGT6- 9000HL(Siemens) | China | Hudian Fuxin Energy | 2 | 386 | 열병합 |

| South Korea | SK | 2 | 405 | ||

| Brazil | Gas Natural Acu | 3 | 388 | ||

| U.K | SSE plc | 1 | 564 | ||

| U.S | Cooperative Energy | 1 | 338 | Repowering | |

| 7HA.01(GE) | U.S | China Energy | 2 | 290 | |

| 7HA.02 (GE) | South Korea | GS Power | 1 | 384 | Combined Heat and Power (CHP) |

| Taiwan | Chiahui Corporation | 1 | 384 | Simple Cycle | |

| Taiwan | TaiwanPower(DanTan8&9) | 4 | 384 | ||

| Brazil | CELEC (Sergipe I) | 3 | 384 | ||

| U.S | Advanced Power | 2 | 384 | ||

| U.S | Caithness Energy | 3 | 384 | ||

| U.S | ESC Harrison County Power | 1 | 384 | ||

| U.S | Fortress Transportation & Infrastructure Investors | 1 | 384 | ||

| U.S | Hill Top Energy | 1 | 384 | ||

| U.S | Indeck Energy Services | 2 | 384 | ||

| U.S | NOVI Energy | 2 | 384 | ||

| U.S | Tampa Electric | 2 | 384 | Repowering | |

| 7HA.03(GE) | U.S | Florida Power & Light | 1 | 430 | |

| Total | 44 | – | 17.29GW | ||

Major Gas Turbine Model Specifications (referenced by 2020 Gas Turbine World Handbook)

| GT Vendoer | MHPS | Siemens | GE | |||||

| GT Model | M501J | M501 JAC | SGT6- 8000H | SGT6- 9000HL | 7HA.01 | 7HA.02 | 7HA.03 | |

| Simple cycle | ||||||||

| Intro year | 2011 | 2015 | 2010 | 2017 | 2012 | 2014 | 2019 | |

| ISO base load (kW) | 300,000 | 425,000 | 310,000 | 405,000 | 290,000 | 384,000 | 430,000 | |

| Heat rate (Btu/kWh) | 8,105 | 7,755 | <8,530 | 8,010 | 8,120 | 8,009 | 7,884 | |

| Efficiency | 42.1% | 44.0% | >40 | 42.6% | 42.0% | 42.6% | 43.3% | |

| Press ratio | 23.0 | 25.0 | 21.0 | 24.0 | 21.6 | 23.1 | 23.7 | |

| Mass flow (lb/sec) | 1,367 | 1,626 | 1,433 | 1,598 | 1,294 | 1,609 | 1,718 | |

| Turbine speed (rpm) | 3,600 | 3,600 | 3,600 | 3,600 | 3,600 | 3,600 | 3,600 | |

| ExhaustTemp (˚F) | 1,176 | 1,201 | 1,193 | 1,238 | 1,158 | 1,202 | 1,217 | |

| Approx. Weight (lb) | 698,870 | 765,000 | 637,000 | 672,400 | 547,000 | 602,000 | 645,000 | |

| Approx. LxWxH (ft) | 50x18x18 | 50x19x19 | 34x14x14 | 35x16x14 | 30x13x14 | 32x13x14 | 34x14x15 | |

| Combined cycle 1×1 | ||||||||

| Gross Plant output (kW) | 485,500 | 615,800 | **** | **** | 443,100 | 580,100 | 650,780 | |

| Net Plant output (kW) | 484,000 | 614,000 | 460,000 | 595,000 | 438,000 | 573,000 | 640,000 | |

| Net Heat rate (Btu/kWh) | 5,504 | 5,332 | 5,611 | <5,416 | 5,481 | 5,381 | 5,342 | |

| Net Plant efficiency | 62.0% | 64.0% | 61.0% | >63% | 62.3% | 63.4% | 63.4% | |

| Net Heat rate (kJ/kWh) | 5,807 | 5,625 | 5920 | <5,714 | 5,783 | 5,677 | 5,677 | |

| Condenser pressure | 1.5 inch Hg | **** | **** | 1.2 inch Hg | ||||

| GT power (kW) | 326,200 | 420,300 | **** | **** | 294,100 | **** | **** | |

| ST power (kW) | 157,800 | 193,700 | **** | **** | 149,000 | **** | **** | |

| Comments | 3P reheat | 3P reheat | ||||||

| Combined cycle 2×1 | ||||||||

| Gross Plant output (kW) | 974,000 | 1,234,700 | **** | **** | 890,700 | 1,162,200 | 1,297,600 | |

| Net Plant output (kW) | 971,000 | 1,231,000 | 930,000 | 1,190,000 | 880,000 | 1,148,000 | 1,282,000 | |

| Net Heat rate (Btu/kWh) | 5,486 | 5,315 | 5,602 | <5,416 | 5,453 | 5,365 | 5,331 | |

| Net Plant efficiency | 62.2% | 64.2% | 61.0% | >63% | 62.6% | 63.6% | >64.0% | |

| Net Heat rate (kJ/kWh) | 5,788 | 5,608 | 5,910 | <5,714 | 5,753 | 5,660 | 5,625 | |

| Condenser pressure | 1.5 inch Hg | **** | **** | 1.2 inch Hg | ||||

| GT power (kW) | 652,400 | 840,600 | **** | **** | 588,200 | 765,000 | 860,000 | |

| ST power (kW) | 318,600 | 390,400 | **** | **** | 302,500 | 397,200 | 437,600 | |

| Comments | 3P reheat | 3P reheat | ||||||

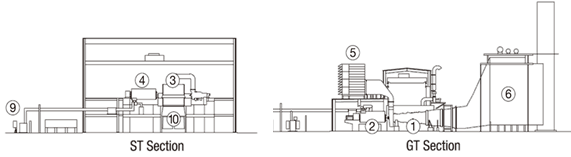

Construction for Gas Power Plant

Installation Layout & Space: To be determined based on the plant configuration and scope of supply

Plant Configuration (Power Block Composition)

– A power block refers to a unit facility for power generation composed of major equipment.

– It is typically configured by the client or bidder based on the power generation scenario, optimizing for output, efficiency, and overall economic performance.

f

< Table : Key Characteristics by Power Block Configuration Type>

| Configuration | 주Key Characteristics |

| Single GT(1-1-1) | – Relatively fast start-up time – Single-shaft or multi-shaft configuration – Lower construction cost due to the use of large gas turbines – When using a single-shaft configuration, a clutch can be included between the GT and ST to allow simple cycle operation |

| Multi GT(2-2-1 또는 3-3-2) | – GT 2sets & ST 1 set ratio is common, but optimization is performed based on various operational scenarios considering the client’s needs (e.g., output, part-load operation, efficiency, etc.) – Possibly accommodate additional purposes such as steam supply – Higher construction cost per unit of power generation capacity |

※ Plant configuration varies depending on the characteristics of power demand and the operational scenario.

Single Shaft | Multi-Shaft 1×1 |

Multi-Shaft 2×1 | Multi-Shaft 3×1 |

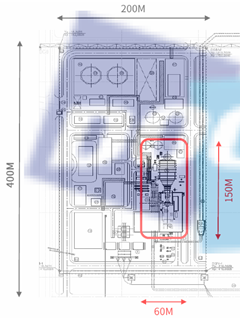

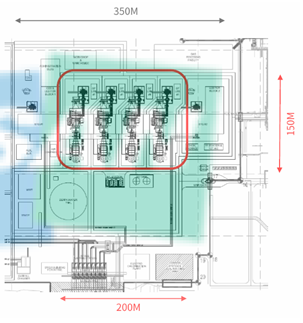

Required Site Space

| Item | 1-1-1 Configuration의 경우 | 4-4-2 Configuration의 경우 |

| Power Block (Required Space) | Over 1 ha (9,000 m2) | Over 3 ha (30,000 m2) |

| Plant (Required Space) | Over 8 ha (80,000 m2) | Over 14 ha (140,000 m2) |

| Layout |  |  C C |

Construction Period:

If there are no special conditions for site preparation, it typically takes 30 to 40 months

| Project | Combined Cycle Power Plant (South Korea) | Combined Cycle Power Plant (South Korea) | Combined Heat and Power (CHP) Plant (South Korea) |

| Total Power | 1,004MW | 1,823MW | 450MW |

| BlockConfiguration | 2-2-1 | 2×(2-2-1) | 1-1-1 |

| Construction Period | 31 Months | 36 Months | 32 Months |

In a recent case, the first ignition occurred 26 months after the start of foundation piling work, and completion followed within 9 months after that—resulting in a total project duration of approximately 31 to 35 months

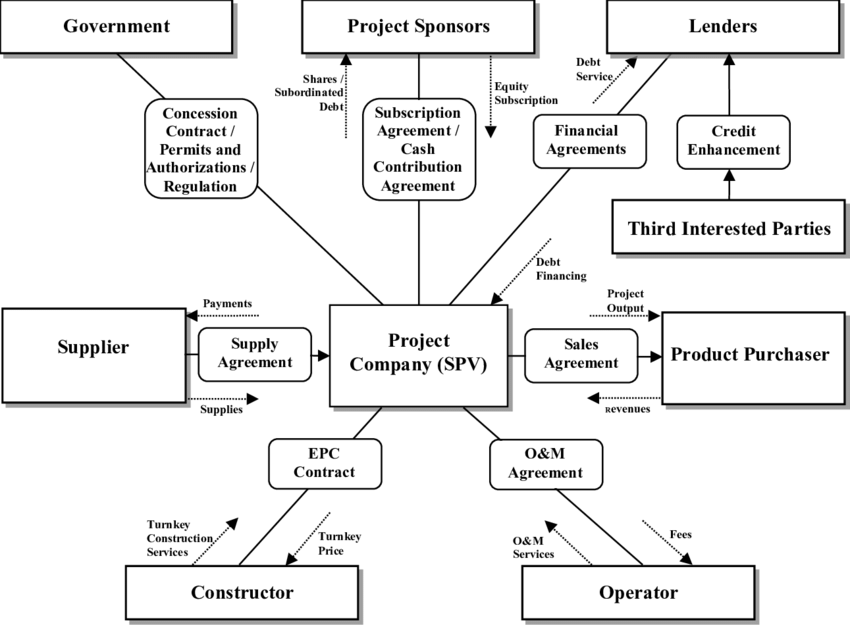

Procurement and Contract Structure

An equipment supply agreement is signed between the EPC contractor and the GT (Gas Turbine) OEM, while a direct LTSA (Long-Term Service Agreement) is executed between the Developer and the GT OEM for services during the operational period.

Considering GT price, performance, and service costs, the GT OEM holds a dominant influence over the overall project

CAPEX & OPEX

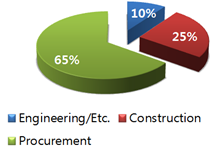

CAPEX Composition:

- Construction CAPEX is broadly categorized into EPC Cost and Non-EPC Cost.

- EPC Cost includes equipment costs (main and auxiliary equipment) and construction expenses.

- Non-EPC Cost comprises design and engineering services, technical support/NDT service fees, land acquisition, owner’s indirect costs (e.g., general administrative expenses, commissioning overheads), and construction interest during the build period.

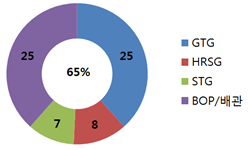

- (EPC Price Breakdown) Among total plant costs, main equipment procurement accounts for approximately 40% of EPC cost. Within this, the gas turbine represents the largest share, typically making up around 25% of the total plant cost.”

| EPC Cost | Procurement Cost |

|  |

OPEX Composition:

- Service (LTSA, Long Term Service agreement and others)

- Utility Consumptions (Water, Chemicals and others)

- Other Administration Cost

| Power Output | Net Construction Cost (Based on S. Korea) | OPEX / yea (Based on S. Korea) | |||

| Total (MMUSD) | USD/kW | Total (MMUSD) | USD/kW/Month | MM USD/Month | |

| 900MW | 625.9 | 0.66 | 23.1 | 0.0029 | 1.92 |

| 450MW | 386.0 | 0.81 | 15.8 | 0.0040 | 1.32 |

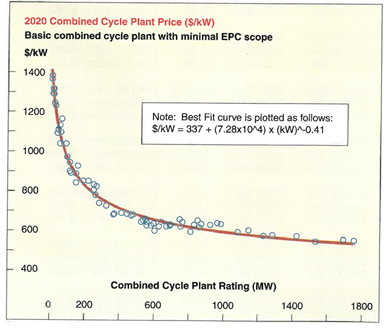

EPC Cost Trends

The gas turbine industry journal Gas Turbine World annually estimates and publishes the minimum EPC costs for combined cycle power plants based on power capacity.

(Minimum equipment basis) According to Doosan Heavy Industries Expert, these estimates tend to be somewhat higher than actual EPC prices, considering that a significant portion of equipment is excluded from the calculation

Global EPC Price Trend (“Minimum Scope”)

EPC cost ($/kW) = 337 + (7.28 × 10⁴) × kW⁻⁰·⁴¹ <Calculation Result >

<Basis of Estimation>

- Turnkey basis (including supply of major equipment, engineering, and construction); accuracy: ±15%

- Exclusions: Owner’s cost, site clearing, fuel transportation, financing costs, optional equipment (bypass stack, inlet cooling, duct firing, catalysts, auxiliary fuel systems), interconnection costs, etc.

- Power output (kW) basis: Net baseload power rating under standard conditions

| 출력 (MW) | EPC cost |

| $/kW | |

| 200 | 825 |

| 400 | 705 |

| 600 | 648 |

| 800 | 614 |

| 1,000 | 589 |

| 1,200 | 571 |

| 1,400 | 557 |

| 1,600 | 545 |

| 1,800 | 535 |

(S. Korea Case) According to the Korea Power Exchange’s status report on power plant construction projects, the recent construction cost for combined cycle power plants in Korea is approximately 700,000 to 1,000,000 KRW per kW.

– However, it is difficult to clearly determine whether transmission/interconnection facilities and site preparation work are included, as these vary depending on site-specific conditions.

– For public power generation companies, Korea Power Engineering Company (KOPEC) typically handles the design, whereas independent power producers (IPPs) generally opt for EPC turnkey contracts covering both design and construction. (Referenced at KPX, etc.)

| EPC Period | Project | Power Output (MW) | EPC Cost (MMUSD) | Unit Cost (USD/kW) | OEM | Design | EPC Contractor | Remarks |

| ‘19.12-’22.7 | Yeoju | 1,004 | 971,000 | 967 | Siemens | SK | ||

| ‘19.2-’20.12 | Nam-Jeju | 173 | 382,088 | 2,209 | GE, Daewoo | KPS | POSCO E&C | |

| ‘17.1-’19.11 | Shin-Pyeongtaek | 943 | 650,000 | 689 | MHPS | POSCO E&C | ||

| ‘16.5-’18.6 | Jeju LNG | 240 | 260,917 | 1,087 | GE | KPS | POSCO E&C | |

| ‘15.8-’17.11 | Yeongnam#1 | 470 | 410,400 | 873 | MHPS, Daewoo | KPS | POSCO E&C | |

| ‘14.8-’17.3 | Daewoo-Pocheon#1 | 960 | 760,000 | 791 | MHPS | Daewoo | ||

| ‘14.7-’17.4 | GSDangjin#4 | 950 | 729,920 | 768 | Siemens | KPS | GS | |

| ‘14.4-’17.7 | Jangmun#1,2 | 1,800 | 1,500,000 | 833 | Siemens | B&V,S&L,SK | SK | |

| ‘13.6-’19.8 | Seoul#1,2 | 800 | 1,018,128 | 1,273 | Doosan | KPS | POSCO E&C | installed at Underground |

(S. Korea) O&M Cost Case Study

Domestic O&M Cost Case Study

A study found that the average ratio of annual operation and maintenance (O&M) costs to capital investment (excluding financing costs) ranges from 3.3% to 5.5% for combined cycle power projects.

– Among the technologies, Siemens H-class showed significantly higher O&M costs.

– Siemens is characterized by relatively lower upfront equipment prices, but higher LTSA (Long-Term Service Agreement) costs.

* Scope of study: Projects with three years of actual O&M cost data from 2014 to 2016 (combined cycle power plants) (Ref. : 2017, KPX)

| Items | M501J (MHPS) | SGT6-8000H (Siemens) |

| Finance Cost (Included) | 5.49% | 7.61% |

| Finance Cost (Excluded) | 3.29% | 5.42% |